Products

Freeze-drying Of Flower Yogurt Food

Name:freeze dryer

Size: from 0.5 to 200m²

Highlight: can be customized

Warranty:one year

Features

Freeze-drying of Flower Yogurt Food

Here, I will explain the production steps of the vacuum freeze dryer in the freeze-drying of flower yogurt food! Due to the unique advantages of vacuum freeze-drying technology, vacuum freeze-drying machines have been widely used in all walks of life. Its freeze-dried flower yogurt includes yogurt, edible flowers and fruit juice (optional accessories). The yogurt crisp prepared by ingredients, injection molding freezing, and vacuum freeze drying has a soft texture and rich colors. And the desire to eat; the yogurt crisp melts in the mouth, and the remaining pieces of flowers are freeze-dried at a low temperature to greatly preserve their original color, fragrance, and taste, so that the floral fragrance fills the entire mouth, giving a very pleasant and comfortable feeling. The deep processing of vacuum freeze dryers helps to improve the level of deep processing of dairy industry and significantly improves the sensory and edible quality of yogurt.

Taking fruit and flower yogurt as an example, the freeze-dried production steps of flower yogurt are as follows:

(1) Preparation of yogurt: The preparation of yogurt is prepared according to the process commonly used in production. After the fermentation is completed, the yogurt is evenly stirred and demulsified until there is no obvious lump.

(2) Preparation of edible flowers: Put the edible flowers into a chopper and cut them into filaments with a size of 1-50 square millimeters or width of 1-30 cm.

(3) Ingredients: edible flowers (1~20), the percentages in parentheses of each raw material in the ingredients are the mass content of yogurt as the base. To increase the color richness of the yogurt, fruit juice can be optionally added.

(4) Injection-molding freezing: The material obtained by stirring evenly in step (3) is injection-molded and divided, and pre-frozen at -30~-50°C for 2~8 hours. The height of the injection molding subassembly material is less than 10 cm, which can shorten the time of vacuum freeze-drying.

(5) Vacuum freeze-drying: sublime and dry the material obtained by pre-freezing in step (4) at a temperature of -20~-50°C and a vacuum degree of 0~200Pa for 5~20h, and at a temperature of -30~50°C and a vacuum degree of 0 Under the condition of ~200Pa, the vacuum freeze-dried fresh flower yogurt was prepared by heating, desorption and drying in stages for 5~20h.

(7) Inspection and packaging: The vacuum-dried yogurt puffs that are loose and porous, no agglomeration, and no peculiar smell are measured and bagged according to the corresponding specifications, vacuumed or filled with nitrogen by a vacuum sealing packaging machine, and then quickly sealed, and stored at 0~25 ℃ . After the analysis and drying are completed, the yogurt puffs should be quickly stored in bags to avoid shortening the shelf life and reducing the taste quality of eating due to the long-term storage of absorbing moisture in the air.

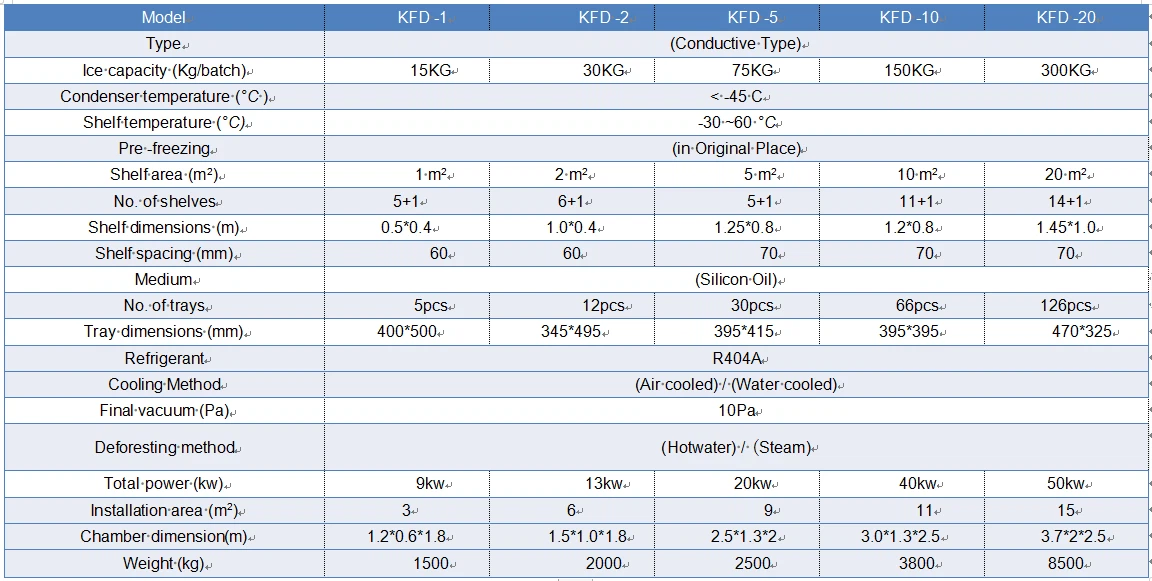

Parameter:

Hot Tags: freeze-drying of flower yogurt food, China freeze-drying of flower yogurt food suppliers, manufacturers, factory, Small Food Freeze Dryer, Matsutake Food Freeze Dryer, Medium Freeze Dryer, Mushroom Food Freeze Dryer, Porridge Freeze Drying Machine, Rice Noodle Food Freeze Dryer

You Might Also Like

Send Inquiry